In today’s manufacturing world, precision doesn’t just matter. Efficiency matters, too. Industries are trending towards smaller and more complex parts. This, in turn, creates the need for advanced welding solutions. Micro welding has become a significant technology. It enables manufacturers to effectively address challenges. These challenges are addressed with precision and efficiency.

The Need for Micro Welding in Production

Pressure to bring high-precision parts to market quickly affects manufacturers across various industries. Micro welding methods enable the precise and secure connection of tiny and delicate components without compromising their integrity.

An Industrial Welding Company will not just possess the expertise. They also have specialized devices necessary to meet these high standards in complex production environments. Investing in such companies has ensured that smaller and detailed tasks are managed efficiently. This is done without wastage and delay in production.

How Micro Welding Improves Production Lines

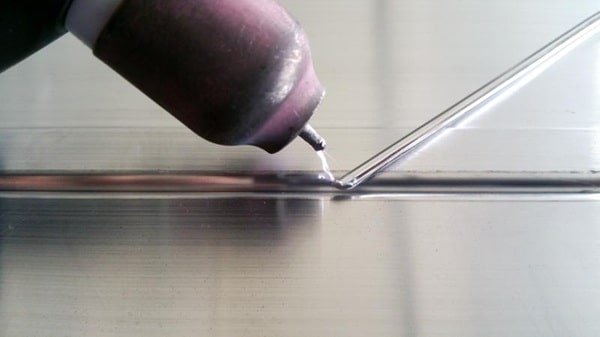

Micro welding technologies revolutionize production through the precision with which they control welding tiny parts. Laser beam welding, as well as microscopic TIG welding, guarantees minimal heat impact and accuracy.

Manufacturers need to maintain quality perfectly, as these methods minimize errors and boost productivity. In addition, these technologies enable seamless integration with automated production lines. This allows for faster throughput without the risk of errors.

The Role of Welding Services in Production

High-volume production of high-quality components requires reliable quality welding services. These services handle complex projects. Usually, they involve using hands-on mixing automation and skilled operators to maintain quality. Implementing these kinds of services, manufacturers can scale up production without compromising precision or reliability.

Production Welding Services also enable businesses to be responsive to market demands. This, in turn, reduces the downtime caused by welding-based problems. These services enable manufacturers to stay current with the growing demand for customized parts.

Additionally, production welding services help ensure that components are welded cost-effectively. With this, you can’t just minimize material waste. You can also reduce the overall production costs. The uniformity of services presented by such services boosts long-term sustainability. This ensures that companies stay competitive and profitable.

Enhancing Efficiency with Micro Welding Techniques

Micro welding techniques add quality and efficiency. Reduced heat input minimizes distortion, and faster welding cycles increase the output. The level of precision ensures that even the smallest components meet strict performance and safety standards. This, in turn, optimizes production flow.

Manufacturers can also gain from cost savings in the maintenance area. That is because these methods put less wear on equipment and materials. The ability to make consistent, high-quality welds directly affects the competitiveness of a production line. With better precision, better tolerances can be achieved. This can also reduce post-welding processes. With this, you can save both time and money.

Industries Leveraging Micro Welding for Production Optimization

A number of industries benefit from micro welding technologies. Some of these industries include the following:

- Electronics manufacturing

- Automotive

- Renewable energy

- Telecommunications

The Role of Businesses

Companies like Micro Weld are considered pioneers in the field. This is true, especially in micro welding technologies. They provide customized solutions for industries with high precision requirements. Their expertise enables manufacturers to undertake complex metal welding projects.

By focusing on innovation, some companies don’t just help clients reduce the time required for production. They help them, too, to improve the reliability of their products. This applies to either small or large-scale manufacturing projects.

Future Innovations in Micro Welding

As manufacturing demands continue to rise, the evolution of micro welding will continue to feature advancements. These advancements are not just seen in automation. They are also seen in robotics and AI. Future production lines will not just be faster. It will also be more accurate and cheaper.

New technologies may include adaptive laser systems. These systems can automatically adjust welding parameters based on real-time feedback. This will enable manufacturers to work on more complex designs.

Additionally, AI and machine learning will help optimize welding processes. They will do so by not just analyzing data in real time. They will also do so by predicting maintenance needs. As these innovations progress, micro welding will become an increasingly integral part of the future of manufacturing. This, in turn, will lead the way in driving efficiency.

The bottom line is that micro welding has revolutionized production lines. It has done so by enabling the precision, efficiency, and reliability of manufacturing miniature components. Techniques such as laser beam and microscopic welding, combined with TIG, are more productive. They help in enhancing quality and reducing the incidence of errors.

With companies propelling innovation, the future of production optimization is looking brighter than ever. Manufacturers that invest in micro welding technologies shouldn’t just anticipate greater productivity. They should also expect reduced operational costs and maintain consistent product excellence. These advancements ensure that industries remain competitive. Plus, they can keep pace with the rising demands of modern manufacturing.